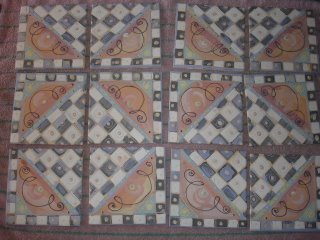

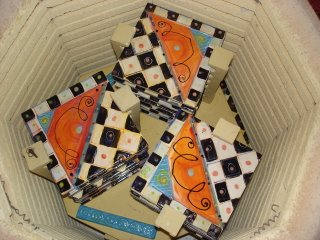

They were put in in a very cool and creative way.

.

This section by the loo looks like a fabric scarf, sliding down the wall!

This blog functions as a behind the scenes look at the process which results in the finished works you can see at my website www.pamdesign.com. In this blog you can see work in progress, read my short comments and my thoughts about what I am working on. Subscribe to my Blog at the link below, or at my ''Profile'' page! Also, visit me on FACEBOOK: Pam Marwede Is PamDesign! https://www.facebook.com/pages/Pam-Marwede-Is-Pamdesign/149610111745527